Die EinDollarBrille

Laut einer Studie der Weltgesundheitsorganisation WHO aus dem Jahr 2019 benötigen rund 950 Millionen Menschen eine Brille, können sich diese aber nicht leisten oder haben keinen Zugang zu augenoptischer Versorgung. Die Folgen: Kinder können dem Unterricht in der Schule nicht folgen. Erwachsene können keine oder keine qualifizierte Arbeit aufnehmen, um ihre Familien zu versorgen.

Das wollen wir ändern.

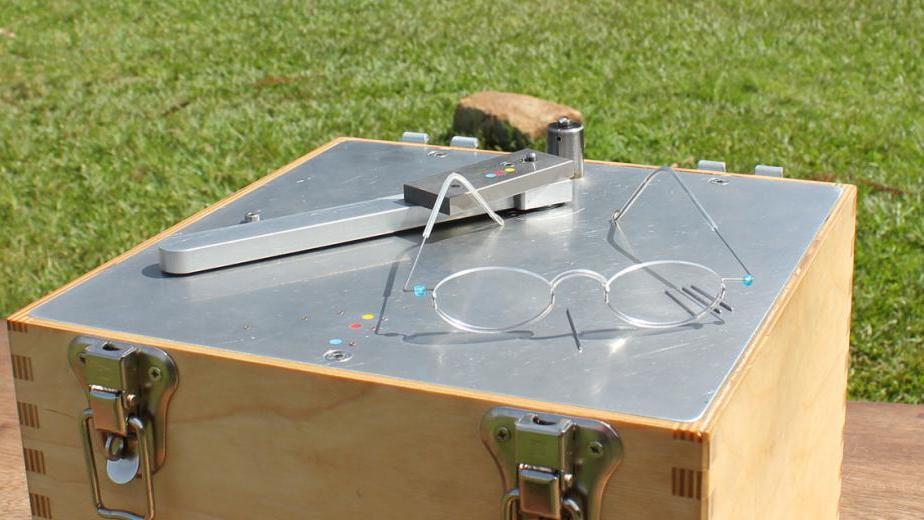

Um das weltweite Problem der unbehandelten Fehlsichtigkeit zu lösen, haben Martin Aufmuth und sein Team das System der EinDollarBrille entwickelt.

Ausbildungskonzept für augenoptische Fachkräfte

Da in vielen Ländern des globalen Südens augenoptisches Fachpersonal fehlt, hat EinDollarBrille e.V. zusammen mit Augenärztinnen und Optikern ein einjähriges Ausbildungskonzept entwickelt. Die darin qualifizierten GoodVision Technicians (GVTs) sind nach Abschluss in der Lage, beim Sehtest zuverlässig das bestmögliche sphärische Brillenglas zu bestimmen und die Brille fachgerecht anzupassen.

Schaffen von Arbeitsplätzen und wirtschaftliche Entwicklung

Der EinDollarBrille e.V. bildet in den Programmländern Fachkräfte für die Herstellung und den Vertrieb der EinDollarBrillen aus. So entstehen auch in Regionen mit schwach entwickeltem Arbeitsmarkt neue Arbeitsplätze mit Perspektive.

Integration benachteiligter Gruppen

In unseren Programmländern bieten wir aktiv Arbeitsplätze für Menschen an, die aufgrund körperlicher Einschränkungen besondere Unterstützung benötigen oder aufgrund ihres Geschlechts benachteiligt sind. Gleicher Lohn für gleiche Arbeit ist dabei selbstverständlich. In unserem Projekt in Burkina Faso beschäftigen wir beispielsweise den ersten blinden Mitarbeiter, der erfolgreich in der Brillenproduktion tätig ist.

Sensibilisierung und Bildung

Durch kostenlose Sehtests, Aufklärungsarbeit in Schulen und Gemeinden und den Aufbau von Beziehungen zu Gesundheitsinstitutionen und NGOs schafft EinDollarBrille e.V. ein wachsendes Bewusstsein für die Bedeutung guten Sehens und die Wirkung von Brillen.

Ziel des EinDollarBrille e.V. ist eine augenoptische Grundversorgung für alle Menschen weltweit.